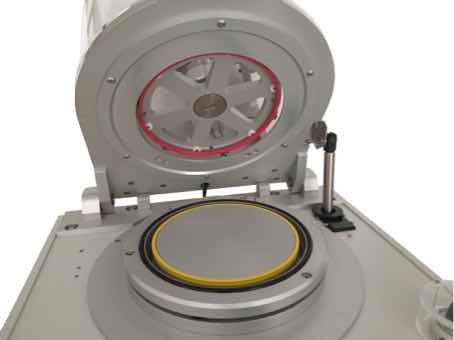

UH104Manual UV curing system

Technical specifications:

• Compact 8" or 12" system

• Manual loading, automatic process

•Rectangular substrates up to 12"

• Environmentally friendly, ozone-free UV lamp

• Fast curing time

• Easily programmable microprocessor based controller

• Repeatable manual operation

• Exceptional cost/performance ratio

• Low temperature 365nm UVA curing process

• Very energy efficient

• Quartz glass window

• Lamp intensity measurement port

Options:

- LED version possible

- Motorized and rotating work platform

- 6" or 8" film frame adapter

- UV Lamp Intensity Radiometer (requires sensor/attenuator assembly, below)

- Sensor/attenuator assembly (requires radiometer above)